Tubería de PVC vs tubería de PE: Una comparación completa de las diferencias clave

Choosing between Tubo de PVC y tubo de PE can be a crucial decision for construction, plomería, y aplicaciones industriales. Ambos tipos de tuberías ofrecen ventajas distintas dependiendo de los requisitos específicos del proyecto. This article explores the key differences between PVC pipe and PE pipe, covering five important factors: raw material composition, flexibilidad, corrosion resistance, applications, and installation/maintenance. Whether you’re looking for affordable pipes for a small project or durable pipes for a large-scale industrial operation, this guide will help you make an informed choice.

1. Raw Material Comparison: PVC pipe vs PE Pipe

Tubo de PVC:

CLORURO DE POLIVINILO (Polyvinyl Chloride) pipes are made from polyvinyl chloride resin, a material known for its lightweight, low-cost, y corrosion-resistant properties. However, Tubo de PVC tend to have lower impact resistance, making them more prone to cracking, especially in cold weather or environments with extreme temperatures. PVC pipe benefits include affordability, but its disadvantages include a higher risk of breakage under impact.

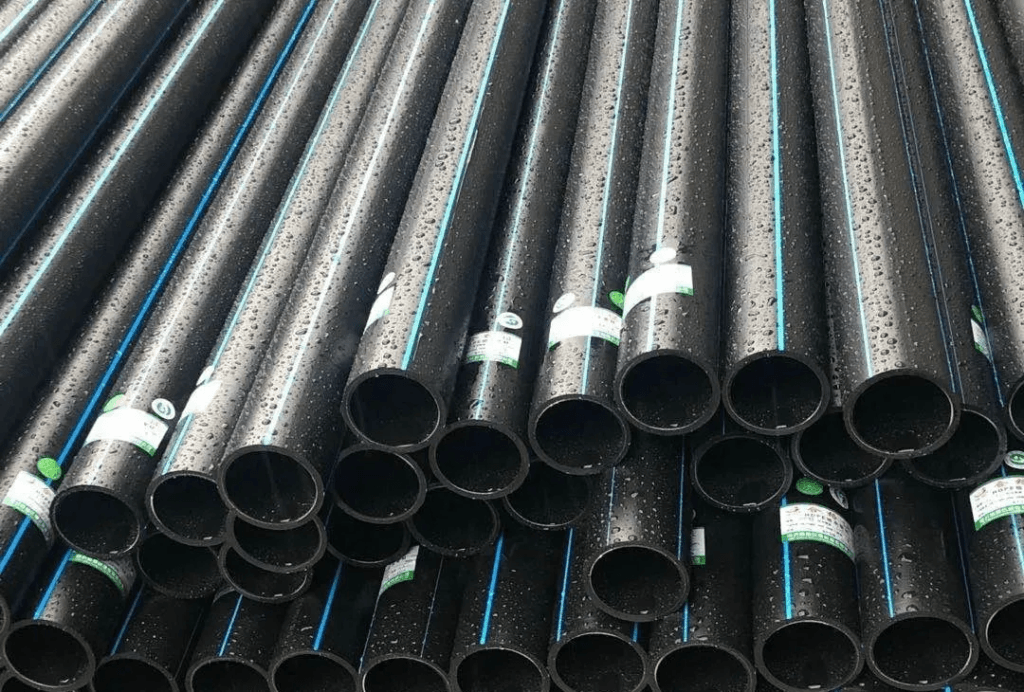

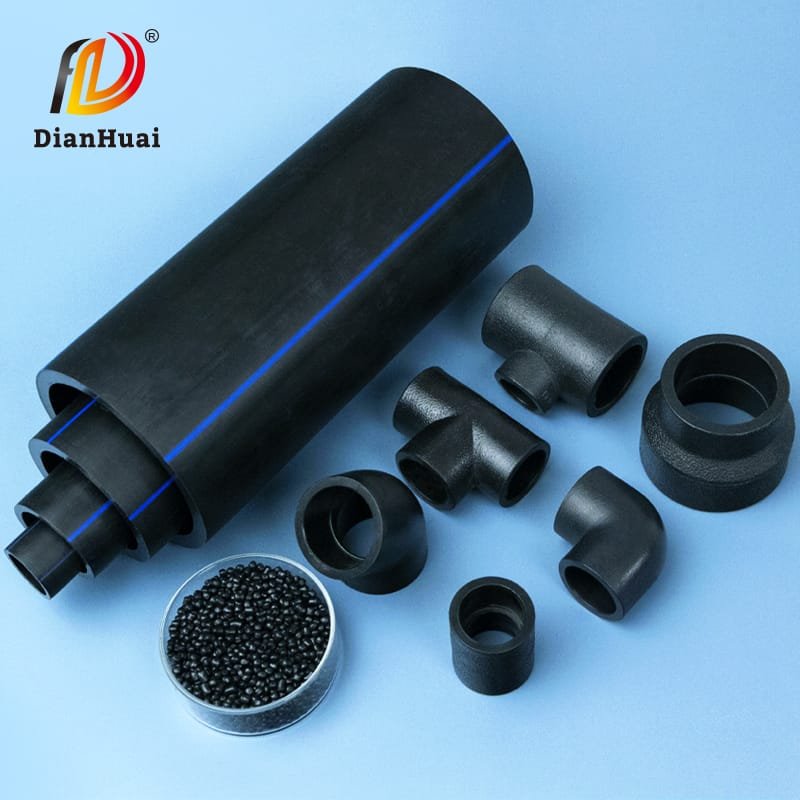

PE Pipe:

Orina (Polyethylene) pipes are manufactured using polyethylene resin, a material with superior flexibility and strength. tubo de PE have excellent impact resistance and can withstand low temperatures much better than PVC. As a result, tubo de PE are widely used in demanding environments and for applications requiring high durability y long-lasting performance.

2. Flexibility Comparison: pvc pipe vs pe Pipe Flexibility

PE Pipe:

The flexibility of PE pipe is one of their strongest attributes. These pipes can be coiled for easy transport, and their flexible design helps reduce the risk of damage from external pressure, such as from soil shifts or concrete installation. This makes tubo de PE ideal for industrial applications, underground installations, and areas with high potential for ground movement. However, tubo de PE are less commonly used for residential plumbing due to their specialized installation requirements.

Tubo de PVC:

PVC pipes are more rigid and less flexible compared to tubo de PE. While they maintain a straight shape and appearance, PVC pipe rigidity can be a disadvantage in environments where bending or flexing is necessary. Their lack of flexibility also makes them more susceptible to breakage under impact. However, this rigidity ensures that Tubo de PVC are easy to install in areas where pipe alignment is important.

3. Resistencia a la corrosión: PVC pipe vs PE Pipe Durability

Tubo de PVC:

Tubo de PVC offer good resistance to most chemicals and general corrosion, making them suitable for a wide range of plumbing and drainage applications. However, CLORURO DE POLIVINILO may degrade when exposed to certain organic solvents o oils. In environments with aggressive chemical exposure, tubo de PE often outperform CLORURO DE POLIVINILO in terms of long-term durability and corrosion resistance.

PE Pipe:

The corrosion resistance of PE pipe is one of their strongest advantages. They are highly resistant to a variety of chemicals, including acids, alkalis, y saltwater, which makes tubo de PE ideal for use in marine environments, industrial settings, and agricultural systems. If you need pipes that can stand up to harsh chemicals and extreme conditions, tubo de PE are a superior choice over Tubo de PVC.

4. Applications: Where to Use PVC pipe and PE Pipes

Tubo de PVC:

Tubo de PVC are commonly used for drainage systems, sewage pipes, rainwater collection, y electrical conduit systems. Because of their low cost and ease of installation, Tubo de PVC are a popular choice for municipal plumbing, residential applications, and small to medium-scale projects. Their cost-effectiveness makes them ideal for large-scale projects where budget is a concern, such as construction projects y sistemas de riego.

PE Pipe:

Due to their strength y durability, tubo de PE are used in more demanding applications, incluido water supply, gas transportation, mining water systems, riego systems, y industrial water distribution. The superior impact resistance y chemical resistance de tubo de PE make them ideal for high-risk environments, where the pipes need to withstand external pressures, químicos, and extreme temperatures.

5. Installation and Maintenance: Ease of Installation and Long-Term Maintenance Costs

Tubo de PVC:

Installing Tubo de PVC is relatively straightforward. They typically use glue or rubber ring connectors, making them easy to assemble. However, since Tubo de PVC are more susceptible to agrietamiento under impact, extra care is needed during the installation process to avoid damage. While Tubo de PVC are generally easy to maintain and have low long-term repair costs, a break in the pipe may require the entire section to be replaced, leading to higher maintenance costs.

PE Pipe:

PE pipe installation is more complex and typically requires fusion welding o electrofusion methods, which require specialized equipment and trained professionals. While the installation process is more costly, PE pipes offer superior impact resistance and can handle greater pressures. The maintenance costs for PE pipes are typically lower, as damaged sections can be repaired without replacing the entire pipe, reducing the overall cost of maintenance.

Conclusión: Choosing the Right Pipe for Your Needs

When deciding between PVC pipes y PE pipes, it’s important to consider the specific needs of your project. PVC pipes are perfect for cost-sensitive applications that don’t require high impact resistance o chemical resistance. On the other hand, if you need a high-performance solution for environments with extreme conditions, high corrosion resistance, and the ability to withstand impact, PE pipes are the superior option.

保持关注

[…] selecting an irrigation system, you must evaluate several critical factors to ensure efficiency and sustainability. These […]